Great idea for a thread, Bryan....here's my ideas for gadgets, some of which have been shown before.

Bowl and platter reversing...apart from the usual Cole jaws for my scroll chuck, I also have a series of replacement 'buttons' that I can use to suit the shape of the rim of bowls that I'm reversing. I didn't set out to buy these, specifically, but can't resist browsing in hardware shops and when I see something that I believe could be useful (and isn't too expensive) I buy it. So, a collection of tap washers, door stops and rubber bungs have now built up and all get frequently used.

Incidentally, the rubber door-stops can be very useful when reversing small items against a friction pad, as a means of pressing them in place, without marking them. They can also be used as a gentle form of support at the tailstock end, for spindle-turned items that tend to 'throw' or wobble when their stem is turned very narrow.

In a similar manner to the collection of Cole-jaw buttons, I'm also building up a variety of buttons and cams for my platter reversing jigs, which I use quite frequently...

I have several compression chucks made of timber. They are all cup-shaped and use hose clips to tighten them. They are very useful for gripping delicate items and especially for hollowing hemi-spherical shapes, to say nothing of safely holding timber that is riddled with splits and cracks....

I keep a set of 'dollies' that can be face-plate of scroll-chuck mounted, these can be concave, or convex and are usually used with a piece of friction-cloth over them.

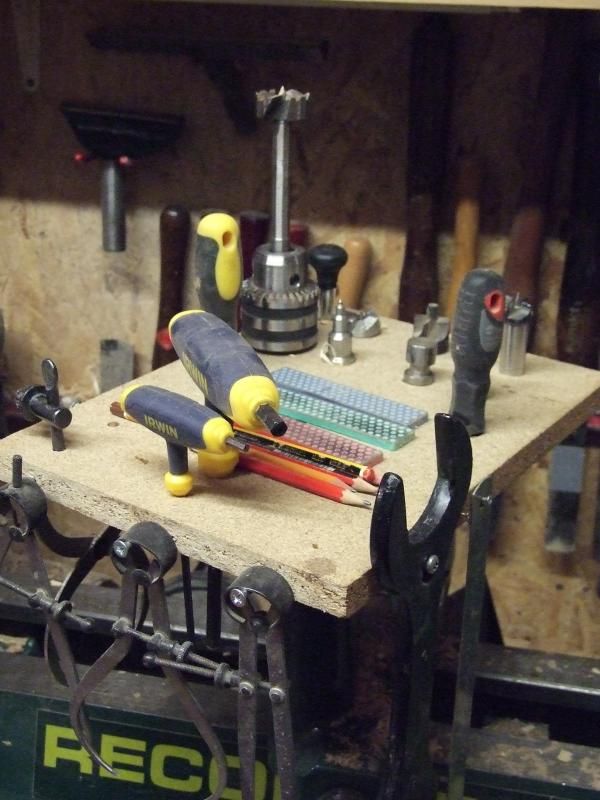

One of the most useful aids that I made a few months ago was a very simple rack that fits into the outboard banjo and holds loads of sundry items that are now easily put back where they belong and I no longer have to go searching for them amongst the shavings. This pic shows it temporarily slipped into the banjo over the bed because I was platter reversing at the time.

....and finally, there's a tool rest that I use in front of my grinder, for scrapers and roughing-out gouges. Being made of wood, there's a lot of friction on the bracket between the base and the table section. This is easily controlled by adjusting the tightness of the securing/pivot bolt, so I can adjust it by just tapping the table on the front or back edge, without having to fiddle with the fixings each time.

No doubt other things will come along as time goes by....I really enjoy thinking about gadgets like this and getting them working efficiently.

Les

p.s. John (BHT)....I turned those hose-clips around